Spindle capping machine

-

Spindle Capping Machine

Special advantages of spindle capping machine:

1. Wide usage, suitable for different kinds of bottles and caps, no need to change spare parts.

2. High speed, it can reach 200bpm.

3. One motor controls one capping wheel, work stably.

4. Can connected with both cap elevator and vibrator. -

4 wheels spindle capping machine

Special advantages of 4 wheels spindle capping machine:

1. Wide usage, suitable for different kinds of bottles and caps, no need to change spare parts.

2. Operator easily

3. VFD controls rotating wheels, work stably.

4. Can connected with both cap elevator and vibrator. -

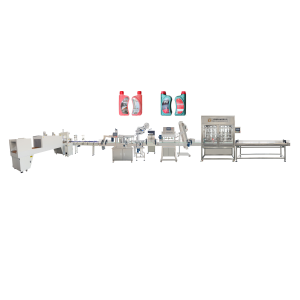

1L lubricant oil 6 nozzles filling capping double side labeling machine line for an Omani customer

1L-5L lubricant oil 6 nozzles filling capping induction sealing double side labeling machine line can finish liquid filling, capping,aluminum foil induction sealing and stickers labeling automatically.

This line canbe widly used for other industrial chemicals, such as engine oil filling line, paint filling line, etc.

-

An Argentine client’s 5L edible oil 12 nozzles filling spindle capping(caps elevator) single side labeling machine line

5L edible oil 12 nozzles filling spindle capping(caps elevator) single side labeling machine line can finish thick liquid filling, capping and labeling automatically.

It can be used for other thick liquid packaging situation,such as tomato sauce filling or honey filling, and the filling volume can be customized.

-

A Ukrainian customer’s 6 nozzles servo barbecue oil filling elevator feeding capping labeling machine line

6 nozzles servo barbecue oil filling elevator feeding capping labeling machine line can finish thick liquid filling, capping and labeling automatically.

It can be used for other thick liquid and liquid packaging situation,such as tomato sauce filling and olive oil filling, and the filling volume can be customized.

-

An Algeria customer’s hand sanitizer liquid soap 4 nozzles servo control filling spindle capping round bottle whole circle and square bottle 3 sides labeling machine line

hand sanitizer liquid soap 4 nozzles servo control filling spindle capping round bottle whole circle labeling machine line can finish liquid filling, capping and labeling automatically.

It can be used for other liquid packaging situation, and the filling volume can be customized.

-

5L engine oil liquid servo controlled piston pump filling capping double sides labeling film wrapping machine line for a Belarusian customer

5L engine oil liquid servo controlled piston pump filling capping double sides labeling film wrapping machine line can finish liquid filling, capping and labeling automatically.

It can be used for other liquid packaging situation, and the filling volume can be customized.

-

Brightwin Round Bottle Filling Capping Whole Circle Labeling Machine Line For A Customer From Dominica

250ml-1000ml hand soap sanitizer liquid filling spindle capping round bottle whole circle labeling machine line, can finish liquid filling capping labeling automatically to save labor cost and increase the production capacity.

-

Brightwin engine oil filling capping labeling machine line for a customer from Saudi Arabia

This line is an automatic 200ml-5000ml filling and packaging line, can finish bottles feeding filling capping labeling and finished bottle collecting automatically, contains: bottles feeding table, engine oil liquid filling machine, elevator feeding caps and 4 wheels spindle capping machine, muti-function (for both round and rectangle bottles) labeling machine and finished bottles collecting turntable.

-

Brightwin lube oil filling line for a customer from USA

This line is an automatic 1L-5l filling and packaging line for an American customer, can finish bottles feeding filling capping labeling and collecting automatically, contains: bottles feeding table, lube oil liquid filling machine, elevator feeding caps and spindle capping machine, double sides labeling machine and finished bottles collecting turntable.